- export5@runpingpp.com

- 24 Hours Online

Industry News

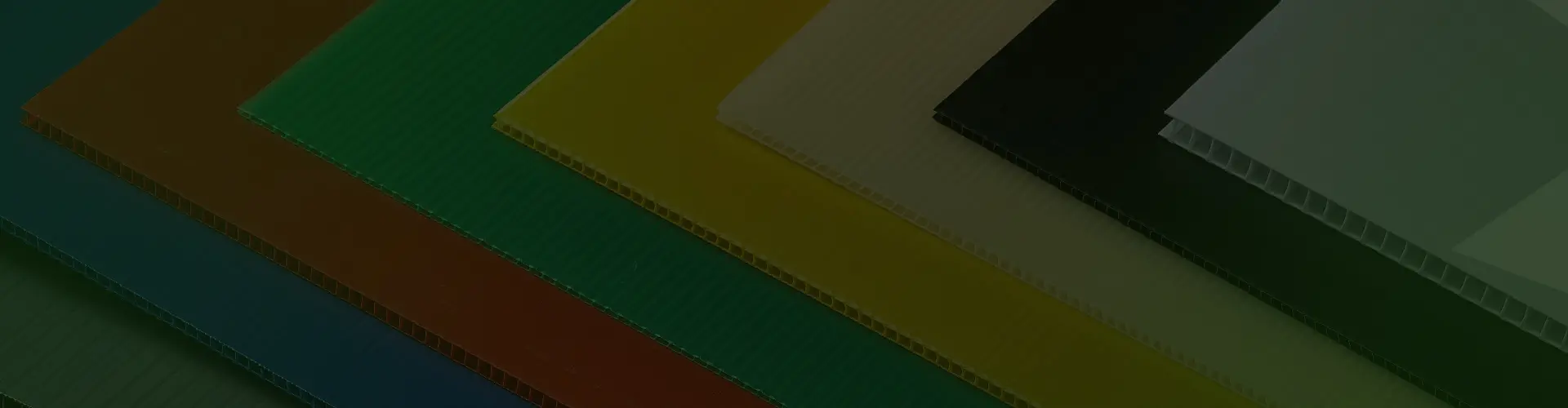

Unlocking Quality: Your Guide to Sourcing the Best Plastic Corrugated Sheets from Reliable Suppliers

In the ever-evolving landscape of packaging and construction materials, Plastic Corrugated Sheets have emerged as a versatile solution favored for their lightweight yet durable characteristics. According to a recent market research report by MarketsandMarkets, the global plastic corrugated sheet market is projected to reach USD 3.6 billion by 2026, growing at a CAGR of 6.12% from 2021 to 2026. This growth is fueled by increasing demands across various industries such as agriculture, logistics, and construction, where the need for sustainable and cost-effective materials is paramount. As businesses seek reliable suppliers to provide high-quality Plastic Corrugated Sheets, it becomes critical to understand the factors that distinguish industry leaders, particularly those that maintain stringent manufacturing standards and innovative practices. In this blog, we will unlock the secrets to sourcing the best Plastic Corrugated Sheets, ensuring your projects benefit from unparalleled quality and reliability.

Understanding the Importance of Quality in Plastic Corrugated Sheets Sourcing

When sourcing plastic corrugated sheets, understanding the importance of quality cannot be overstated. High-quality plastic sheets can enhance durability, reduce material waste, and improve overall product performance. According to a Plastics Industry Association report, the demand for quality plastic products has increased by 15% in recent years, emphasizing the need for businesses to prioritize sourcing practices that assure superior quality. Ensuring that your supplier uses top-grade raw materials and adheres to stringent manufacturing standards is essential for achieving optimal results.

Tip: Always request material certifications and test results from suppliers. This will assure you of the sheet's resilience and compliance with relevant industry standards.

Additionally, working with reliable suppliers can significantly affect the cost-efficiency of your sourcing process. High-quality corrugated sheets are less prone to damage during handling and transportation, which can ultimately save costs associated with replacements. The 2022 Global Plastics Market report reveals that 30% of suppliers that prioritize quality over price have better profit margins and more satisfied clients. By choosing suppliers known for their commitment to quality, you improve not only the end product but also your business's reputation.

Tip: Establish long-term relationships with suppliers that consistently deliver quality products, as this can lead to better pricing and terms over time.

Key Characteristics to Evaluate When Choosing Plastic Corrugated Sheet Suppliers

When selecting plastic corrugated sheet suppliers, it is essential to evaluate several key characteristics to ensure you are sourcing high-quality products. One critical factor is the supplier's production capacity. According to a report by MarketsandMarkets, the plastic corrugated sheets market is projected to reach $2.7 billion by 2026, driven by the rising demand across various industries, including packaging and construction. A supplier with sufficient production capabilities can meet fluctuating demands without compromising quality.

Another important characteristic to consider is the supplier's quality control processes. The International Organization for Standardization (ISO) has set quality management benchmarks that suppliers should adhere to. Transparent quality assurance methods, such as regular testing and adherence to ISO 9001 standards, can significantly impact the longevity and performance of plastic corrugated sheets. In addition, suppliers with a proven track record of innovation—such as using recycled materials or developing lightweight alternatives—are likely more capable of adapting to market trends and environmental regulations.

Lastly, consider the supplier's customer service and support infrastructure. A study by Grand View Research highlights that exceptional customer service directly correlates with higher customer satisfaction and retention rates in the manufacturing sector. Suppliers who offer responsive communication and comprehensive support can help you navigate any challenges, ensuring that your sourcing process is smooth and effective.

The Impact of Material Standards on Plastic Corrugated Sheet Durability

When it comes to plastic corrugated sheets, understanding material standards is crucial for ensuring durability. The quality of the raw materials used significantly impacts the overall performance of these sheets. High-grade polypropylene or polyethylene tends to offer enhanced strength and resistance to environmental factors, such as UV light and moisture, which can lead to degradation over time. Suppliers adhering to strict material standards are more likely to provide products that withstand wear and tear, ensuring longevity and reliability in various applications, from packaging to construction.

Moreover, certifications from recognized industry bodies can serve as a reliable benchmark for assessing the quality of plastic corrugated sheets. For example, sheets that meet ISO or ASTM standards are tested for impact resistance and dimensional stability, which are indicative of their durability. By sourcing sheets from suppliers that comply with these rigorous standards, businesses can mitigate risks associated with premature failure, ultimately reducing replacement costs and enhancing operational efficiency. Users should prioritize suppliers that transparently share their material specifications and testing results to make informed purchasing decisions.

Unlocking Quality: Your Guide to Sourcing the Best Plastic Corrugated Sheets from Reliable Suppliers - The Impact of Material Standards on Plastic Corrugated Sheet Durability

| Supplier Location | Material Grade | Sheet Thickness (mm) | Durability Rating | Certifications |

|---|---|---|---|---|

| USA | PP-Corrugated | 3 | High | ISO 9001, ASTM D7264 |

| Germany | HDPE | 5 | Very High | REACH, CE |

| China | Biaxially Oriented Polypropylene (BOPP) | 4 | Moderate | ISO 14001 |

| India | Polypropylene (PP) | 2 | Low | BIS |

| Brazil | Recycled PP | 4 | High | Green Seal |

Top Challenges in Sourcing Plastic Corrugated Sheets and How to Overcome Them

Sourcing plastic corrugated sheets can present several challenges that manufacturers and buyers must navigate to secure high-quality materials. One of the primary concerns is identifying reliable suppliers, especially in a market flooded with options. According to a 2022 industry report by Smithers, the global demand for corrugated plastics is projected to reach 1.73 million tons by 2026, emphasizing the need for stringent supplier vetting processes. Companies should consider factors such as production capacity, material certifications, and previous client reviews to ensure they partner with trusted suppliers.

Another significant challenge is managing variability in product quality, which can lead to inconsistent performance in end-use applications. A study by Plastics Industry Association revealed that over 40% of manufacturers reported issues with quality consistency, which can hinder operational efficiency. To mitigate these risks, it is crucial to implement rigorous quality control measures and conduct regular audits of suppliers. Furthermore, investing in detailed supplier agreements and establishing clear specifications can help align expectations and reduce discrepancies, ultimately leading to a more successful sourcing strategy.

Data-Driven Insights: Trends in Plastic Corrugated Sheet Quality Control Measures

In recent years, the packaging and construction industries have seen a significant rise in the demand for plastic corrugated sheets. According to a report by MarketsandMarkets, the global plastic corrugated sheets market is projected to reach USD 3.2 billion by 2026, growing at a CAGR of 4.9%. As the market expands, so does the need for stringent quality control measures to ensure these materials meet industry standards. Effective quality control systems not only improve product durability but also enhance overall customer satisfaction.

Implementing data-driven quality control measures is essential for suppliers aiming to stay competitive. Industry leaders have begun leveraging real-time data analytics to monitor production processes and material integrity. A recent survey from the International Journal of Advanced Manufacturing Technology revealed that 70% of manufacturers that utilized data analytics in their quality checks reported a 30% reduction in defects. This trend underscores the necessity for suppliers to invest in technology that accurately tracks product performance metrics.

Tips for ensuring high-quality plastic corrugated sheets include: First, always request certificates of compliance from suppliers to verify that their products meet relevant industry standards. Second, conduct regular audits of your suppliers’ production facilities to assess their adherence to quality control protocols. Lastly, consider utilizing third-party testing services to evaluate the mechanical and thermal properties of sheets before finalizing your purchase.