- export5@runpingpp.com

- 24 Hours Online

Industry News

The Ultimate Guide to Understanding Corrugated Pp Box Features Benefits and Applications

In today's fast-paced world of packaging, the importance of selecting the right materials cannot be overstated, and the Corrugated Pp Box stands out as a top contender. This ultimate guide aims to delve into the unique features, benefits, and diverse applications of Corrugated Pp Boxes, while also exploring the various alternatives available in the market. With their lightweight yet sturdy design, these boxes offer unmatched protection and versatility for a wide range of products, making them a favorite among manufacturers and retailers alike.

As businesses strive to adapt to changing consumer demands and sustainability concerns, understanding the myriad options, including the innovative alternatives to traditional packaging, becomes crucial. Join us as we uncover the essential insights that will help you make informed decisions when it comes to the best packaging solutions for your needs.

Key Features of Corrugated PP Boxes: A Detailed Breakdown

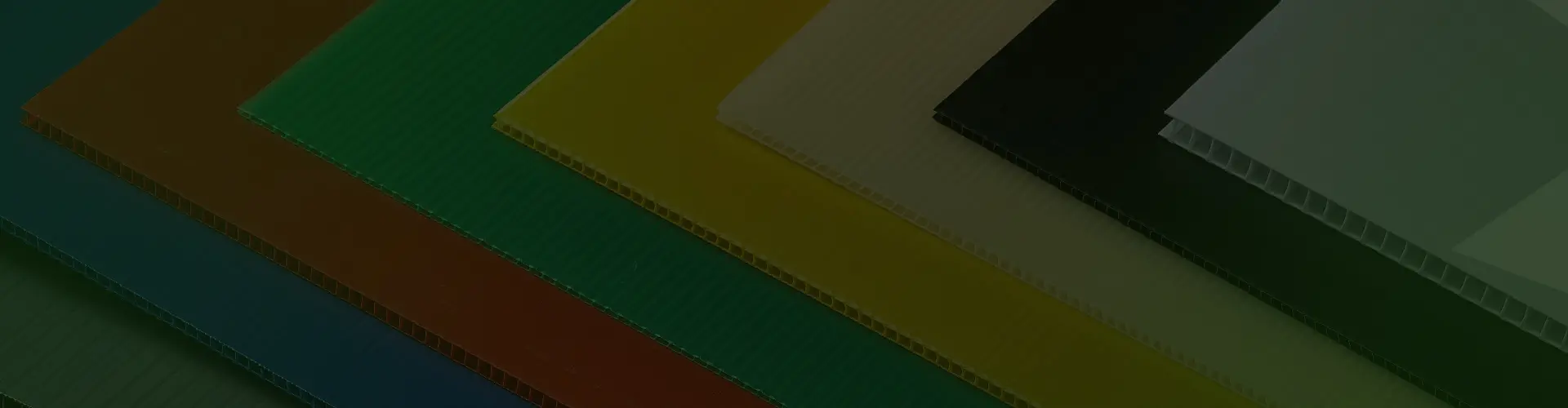

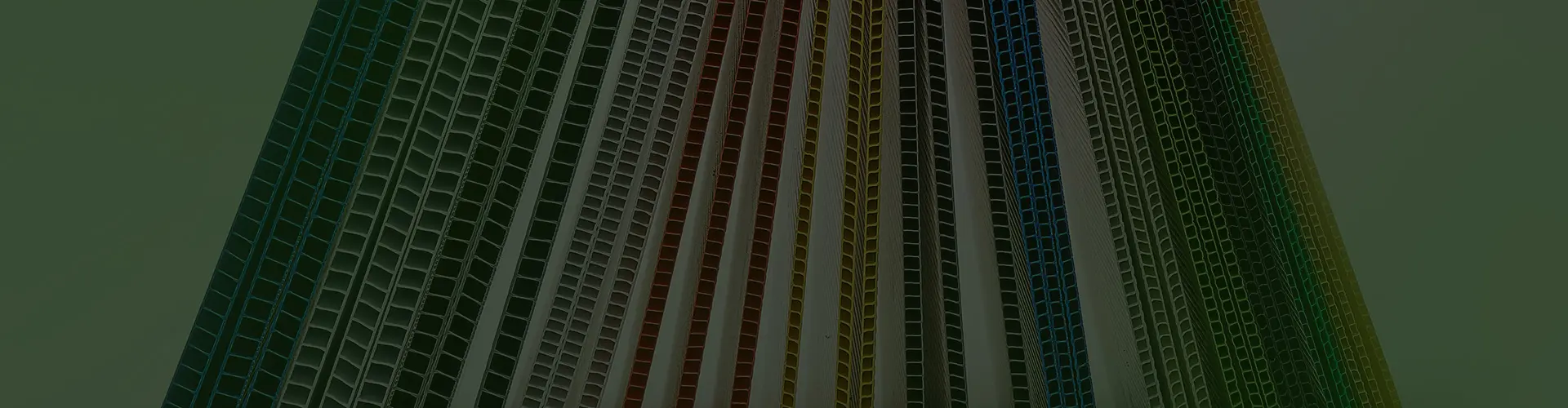

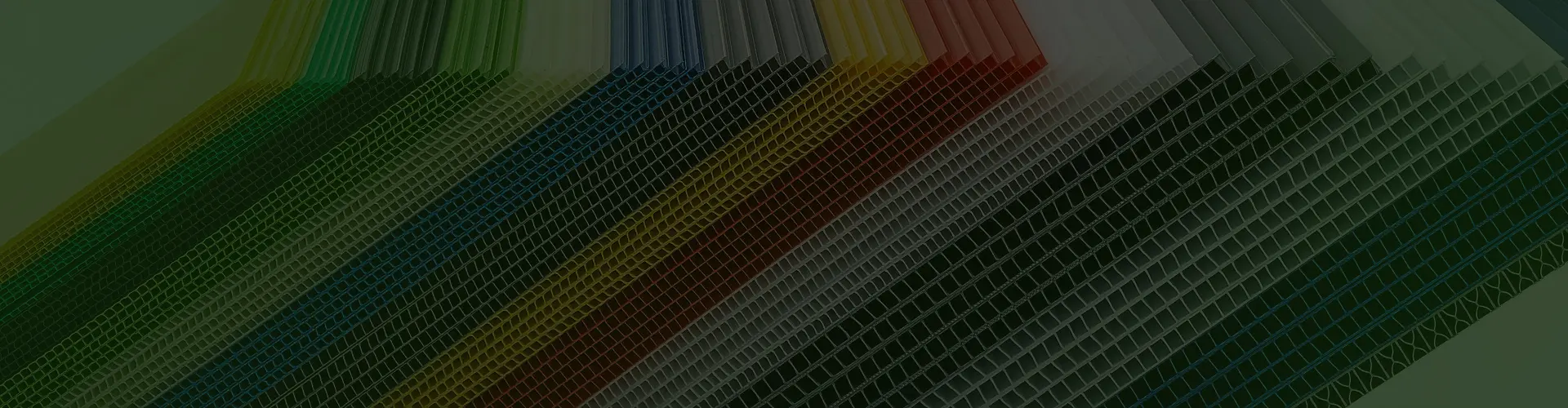

Corrugated polypropylene (PP) boxes are becoming increasingly popular in various industries due to their unique features and benefits. One of the standout characteristics of corrugated PP boxes is their lightweight yet sturdy construction, making them ideal for transporting goods without adding excessive weight. Additionally, these boxes are water-resistant, providing a crucial advantage for products that need protection from moisture. As the demand for sustainable packaging solutions rises, the reusable nature of corrugated PP boxes allows companies to minimize waste and reduce their carbon footprint, aligning with global sustainability goals.

Market trends indicate a significant growth trajectory for corrugated board packaging, with projections estimating its value to reach $191.50 billion by 2032, driven by an increasing demand for eco-friendly packaging solutions. The reusable corrugated plastic boxes market is also thriving, with an estimated size of USD 7.74 billion in 2022 and a remarkable anticipated CAGR of 5.7% from 2023 onward. Such growth reflects the industry’s adaptability amidst challenges like price hikes and supply chain issues, highlighting the importance of innovative packaging solutions in navigating a competitive landscape.

The Ultimate Guide to Understanding Corrugated PP Box Features Benefits and Applications

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Lightweight | Made from polypropylene, ensuring low weight. | Reduces shipping costs and is easier to handle. | E-commerce packaging, retail products. |

| Water Resistant | Manufactured to resist moisture and spills. | Increases product longevity during transport. | Food packaging, electronics shipping. |

| Durability | Strong structure allows for heavy loads. | Protects contents from damage. | Industrial packaging, machinery parts. |

| Eco-Friendly | Recyclable and made from renewable resources. | Supports sustainable practices. | Green packaging solutions, retail. |

| Customizable | Available in various sizes and colors. | Enhances brand visibility and aesthetics. | Promotional packaging, retail displays. |

The Advantages of Choosing Corrugated PP Boxes for Packaging

The rising demand for sustainable packaging solutions has made

corrugated PP boxes an increasingly popular choice across various industries.

These boxes, made from durable and lightweight polypropylene, offer numerous advantages that enhance both functionality and environmental responsibility.

According to industry reports, the global corrugated board packaging market is projected to reach a staggering

$191.50 billion by 2032, reflecting a notable compound annual growth rate (CAGR).

This growth highlights the shift towards materials that are not only strong and versatile but also align with eco-friendly practices.

One significant benefit of corrugated PP boxes is their robustness, which provides excellent protection for products during transportation and storage.

Unlike traditional cardboard boxes, these containers are water-resistant and can be reused multiple times, significantly reducing waste. As various regions,

including Luxembourg, consider stricter regulations on single-use packaging, the emphasis on reusable options is more pronounced than ever.

With initiatives pushing for a reduction in cardboard waste, industries are recognizing the necessity of adopting durable and sustainable practices.

Thus, investing in corrugated PP boxes not only meets regulatory demands but also helps businesses contribute to a more sustainable future.

Applications of Corrugated PP Boxes in Various Industries

Corrugated PP boxes have become increasingly indispensable across various industries due to their superior durability, lightweight nature, and versatility. In the packaging world, the global corrugated packaging market is anticipated to reach $500 billion by 2025, according to a report by Smithers Pira. This significant growth is driven by the rising demand for sustainable and efficient packaging solutions, with corrugated PP boxes being a prime example. Their ability to withstand harsh conditions has made them essential in sectors such as food and beverage, electronics, and pharmaceuticals.

In the food and beverage industry, corrugated PP boxes excel due to their moisture resistance and hygienic properties, ensuring safe transportation of perishables. Moreover, in the electronics sector, their lightweight yet robust structure offers protection against impact, thus reducing damage during shipping. As per a report by the Packaging Association, the adoption of corrugated plastic packaging is expected to grow by 15% annually, showcasing its effectiveness in safeguarding delicate items. Similarly, in the pharmaceutical industry, these boxes provide tamper-proof features, which are crucial for maintaining the integrity of medicinal products. As industries continue to focus on sustainability and efficiency, the application of corrugated PP boxes is set to expand, contributing to reduced waste and enhanced supply chain operations.

How to Properly Use and Maintain Corrugated PP Boxes for Longevity

Properly using and maintaining corrugated PP (polypropylene) boxes is essential for maximizing their lifespan and functionality. Firstly, when utilizing these boxes, it’s important to follow some best practices. Always ensure that the boxes are not overloaded beyond their weight capacity, as this can lead to structural integrity issues. When stacking, distribute the weight evenly and avoid placing excessive pressure on any one box. Additionally, storing these boxes in a dry, cool area away from direct sunlight can prevent deterioration of the material.

Properly using and maintaining corrugated PP (polypropylene) boxes is essential for maximizing their lifespan and functionality. Firstly, when utilizing these boxes, it’s important to follow some best practices. Always ensure that the boxes are not overloaded beyond their weight capacity, as this can lead to structural integrity issues. When stacking, distribute the weight evenly and avoid placing excessive pressure on any one box. Additionally, storing these boxes in a dry, cool area away from direct sunlight can prevent deterioration of the material.

Regular maintenance is key to prolonging the life of corrugated PP boxes. After each use, inspect the boxes for any signs of wear or damage, such as tears or deformation. Cleaning them with mild soapy water can help maintain hygiene, especially if they’re used for storing food products. It’s also advisable to flatten the boxes when not in use to save space and minimize the risk of damage. By following these practices, you can ensure that your corrugated PP boxes remain durable and reliable for a long time.

Comparing Corrugated PP Boxes with Other Packaging Materials: Pros and Cons

When it comes to choosing the right packaging solution, understanding the pros and cons of

corrugated PP boxes compared to other materials is crucial.

Corrugated PP boxes are known for their lightweight nature and excellent durability,

which makes them a preferred choice in various industries. According to a recent market report

by Smithers Pira, the global demand for PP packaging has surged by 4.6%

annually, partly due to its recyclable properties and resistance to moisture. In contrast,

traditional cardboard offers a lower initial cost but lacks water-resistance,

making it less sustainable in wet environments.

Tip: When selecting packaging materials, consider the

environmental impact and lifecycle of the product. Corrugated PP boxes can be reused multiple

times, leading to reduced waste and lower costs over time.

Another key aspect where corrugated PP boxes outperform

others is in their versatility. They can be customized for different shapes and sizes,

providing manufacturers with tailored solutions for their specific needs. However, some businesses

might find the initial investment in PP packaging to be higher than that for cardboard. Yet,

a study by the Packaging Association found that companies often achieve a

return on investment (ROI) within 12 months due to reduced

product damage and lower shipping costs associated with the durability of corrugated PP.

Tip: Always evaluate the total cost of ownership

rather than just the upfront costs. Investing in durable packaging can lead to fewer damages

and increased customer satisfaction in the long run.

Related Posts

-

Innovative Uses of Best Corrugated Pp Box in Various Industries Around the Globe

-

Top Strategies for Sourcing the Best Corrugated Pp Box Globally

-

Innovative Solutions for Efficiently Utilizing Corrugated Plastic Bins

-

Ultimate Guide to Creating Effective Corrugated Signs for Your Business

-

Discovering Quality Suppliers for Best White Corrugated Sign Boards Effective Strategies for Global Buyers

-

7 Reasons Best Corrugated Plastic Totes Are Revolutionizing Supply Chain Efficiency