- export5@runpingpp.com

- 24 Hours Online

Industry News

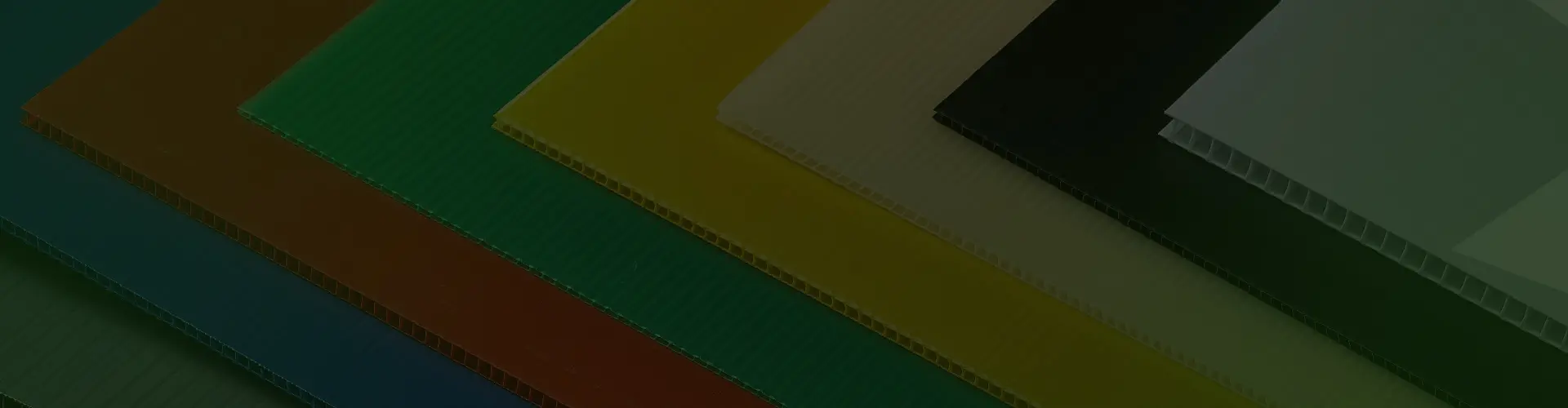

Crafted with Precision Premium Corrugated Plastic Box Manufacturing for Global Supply Chain Excellence

In today's fast-paced and dynamic global supply chain landscape, the importance of durable and versatile packaging solutions cannot be overstated. Among these solutions, the Corrugated Plastic Box stands out as a prime example of innovation in packaging technology. Crafted with precision, these boxes not only offer exceptional strength and resilience but also cater to a wide range of industries and applications. As businesses continuously strive for operational excellence, understanding the comparative advantages of premium corrugated plastic box manufacturing becomes essential. This blog will delve into the myriad benefits and features that set these boxes apart from traditional packaging options, highlighting their role in enhancing efficiency, sustainability, and cost-effectiveness across the supply chain. Join us as we explore how embracing the advanced capabilities of corrugated plastic boxes can elevate your logistics and distribution strategies to new heights.

Innovative Features of Premium Corrugated Plastic Boxes in Supply Chains

In the realm of supply chain excellence, premium corrugated plastic boxes have emerged as a game-changer, offering innovative features that enhance logistics efficiency. According to a recent report by Smithers Pira, the global market for corrugated packaging is expected to reach $296 billion by 2025, driven significantly by the increasing demand for lightweight, durable packaging solutions. The exceptional strength-to-weight ratio of premium corrugated plastic boxes not only reduces transportation costs but also minimizes the carbon footprint, aligning with the growing trend towards sustainability in supply chain operations.

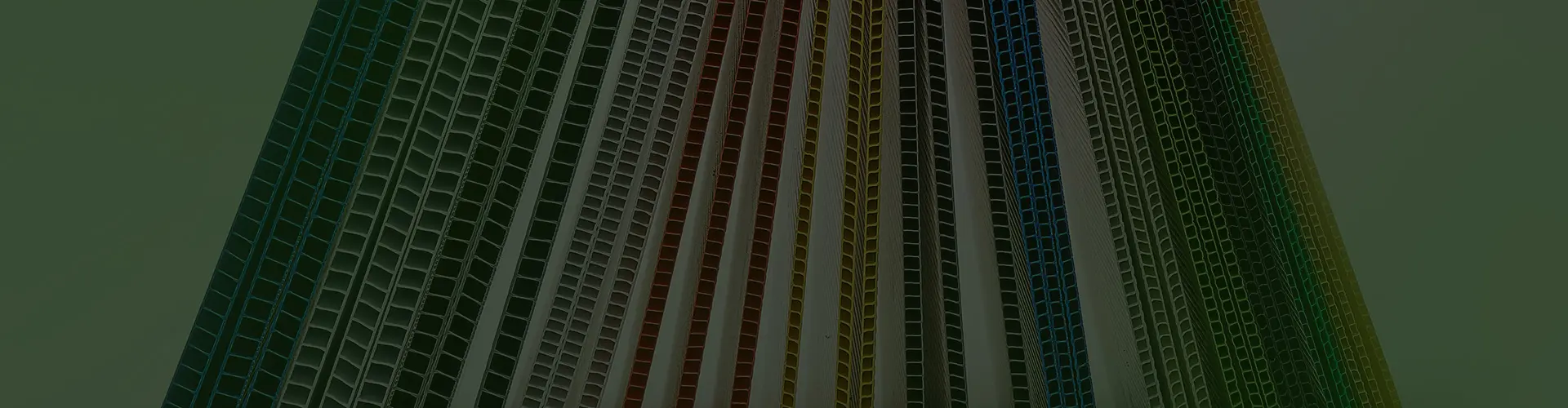

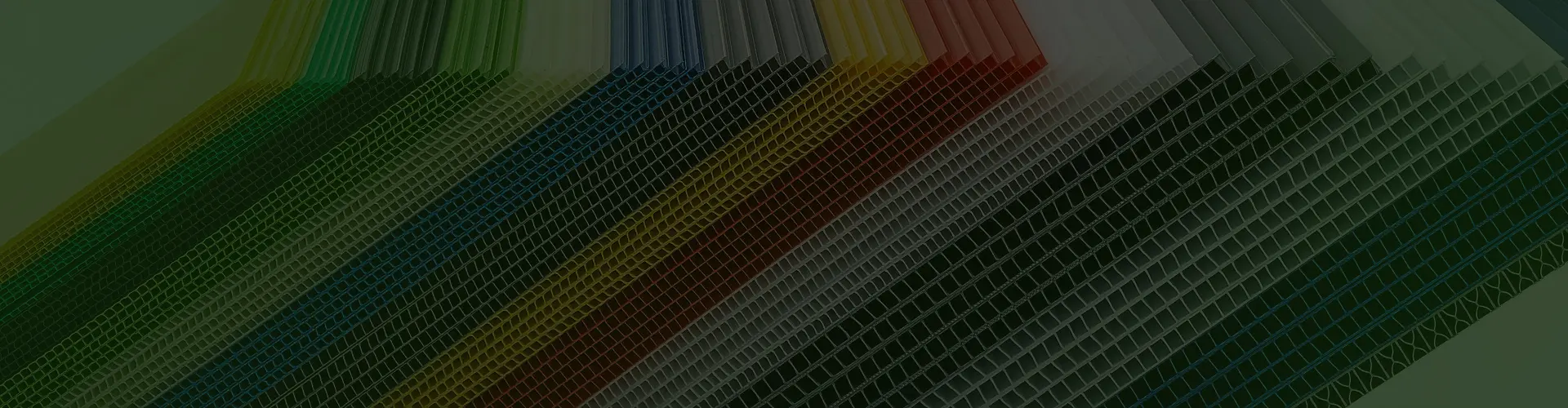

Furthermore, the versatility of these boxes is another key advantage. Industry statistics indicate that over 60% of businesses are shifting from traditional packaging materials to more adaptable options that can withstand various environmental conditions. Premium corrugated plastic boxes are resistant to moisture, chemicals, and pests, making them ideal for transporting sensitive goods in diverse industries. Their ability to be customized in shape and size also caters to specific product needs, thereby reducing wastage and enhancing product protection during transit, which is critical in maintaining the integrity of the supply chain.

Key Benefits of Using Corrugated Plastic for Global Shipping Solutions

In today's global supply chain landscape, the utilization of corrugated plastic boxes stands out as a game-changer for shipping solutions. One of the key benefits of these boxes is their durability and lightweight design, which significantly reduces transportation costs and minimizes carbon footprints. By using corrugated plastic, businesses can ensure that their products are well-protected during transit, mitigating damage and enhancing overall efficiency in logistics.

Moreover, as the focus shifts towards sustainable practices, corrugated plastic boxes align perfectly with emerging trends in eco-friendly packaging. With a growing emphasis on the circular economy and a reduction in virgin plastic usage, companies are increasingly adopting recyclable and reusable materials for their packaging needs. The global market for reusable corrugated plastic boxes is projected to expand, reflecting a wider recognition of the environmental benefits they offer. As businesses strive for sustainability, incorporating such innovative packaging solutions can not only meet regulatory demands but also resonate with eco-conscious consumers.

Crafted with Precision: Premium Corrugated Plastic Box Manufacturing for Global Supply Chain Excellence - Key Benefits of Using Corrugated Plastic for Global Shipping Solutions

| Benefit | Description | Impact on Supply Chain | Sustainability Feature |

|---|---|---|---|

| Lightweight | Easier handling and reduced shipping costs. | Increases overall efficiency in logistics. | 100% recyclable material. |

| Durability | Resistant to impact and weather conditions. | Reduces damage rates during transit. | Long lifespan promotes sustainability. |

| Water Resistance | Protection from moisture and spills. | Ensures cargo integrity and reduces losses. | Reusable and recyclable for eco-friendliness. |

| Customizability | Easily customizable to fit specific needs. | Increases versatility for various products. | Production efficiency reduces waste. |

| Cost-Effectiveness | Lower total cost during lifecycle. | Enhances profitability in shipping operations. | Facilitates the use of sustainable materials. |

Tips for Selecting the Right Corrugated Box for Your Business Needs

When selecting the right corrugated box for your business needs, it's essential to consider several factors that can impact both functionality and cost-effectiveness. First, assess the type of goods you plan to ship. The weight, dimensions, and fragility of your products play a vital role in determining the box style and material thickness required. For heavier items, opting for double-wall corrugated boxes can provide the necessary strength and durability, ensuring safe transportation.

Another key aspect to consider is the environmental impact of your packaging choice. With increasing consumer awareness regarding sustainability, selecting recyclable or biodegradable corrugated boxes not only aligns with eco-friendly practices but also enhances your brand image. Furthermore, consider the design of the box; custom printing and branding on corrugated boxes can add value and help your products stand out in a competitive market. By thoughtfully evaluating these elements, businesses can make informed decisions that contribute to a streamlined supply chain while meeting customer expectations.

The Role of Precision Manufacturing in Enhancing Packaging Efficiency

In today's competitive landscape, precision manufacturing plays a pivotal role in enhancing packaging efficiency, particularly in the production of premium corrugated plastic boxes. As the global market for precision turned product manufacturing is expected to surge to USD 196.11 billion by 2034, manufacturers must focus on adopting advanced technologies to streamline their processes. The integration of Industry 4.0 innovations, including artificial intelligence and the Industrial Internet of Things, is reshaping traditional manufacturing paradigms, allowing companies to produce consistently high-quality packaging solutions while reducing operational costs.

Artificial intelligence has proven to be a transformative force in manufacturing by increasing reliability and efficiency. By automating various stages of production, companies can minimize waste and optimize resource utilization—key factors that contribute to sustainable practices in packaging manufacturing. Additionally, the adoption of robotics is revolutionizing precision manufacturing for a range of applications, ensuring that every corrugated plastic box meets exacting standards. As the industry progresses, leveraging these technologies will be critical in driving the future of packaging efficiency and excellence in the global supply chain.

Sustainability Practices in Corrugated Plastic Box Production

Sustainability has become a critical focus in the manufacturing sector, particularly in the production of corrugated plastic boxes. These lightweight yet durable packaging solutions are increasingly being recognized for their eco-friendly attributes. According to a 2022 report by the Global Plastic Packaging Market, the corrugated plastic segment is projected to grow at a CAGR of 5.1% to reach USD 30 billion by 2026. This surge is driven not only by the demand for superior packaging solutions but also by the industry’s commitment to reducing its carbon footprint.

One of the standout sustainability practices in corrugated plastic box production is the use of recycled materials. Industry data indicates that utilizing recycled plastics can reduce energy consumption by up to 80% compared to using virgin materials. Many manufacturers are adopting closed-loop systems that ensure the recycling of materials at the end of their life cycle, enabling a significant reduction in landfill waste. Additionally, innovative manufacturing techniques, such as 3D printing and advanced molding processes, are being implemented to enhance efficiency and minimize material wastage. This commitment to sustainable practices not only meets regulatory requirements but also aligns with consumer expectations for environmentally responsible products.