- export5@runpingpp.com

- 24 Hours Online

Industry News

Ultimate Guide to Choosing the Right Corrugated Plastic Rolls for Your Business Needs

In today’s competitive business landscape, selecting the right materials can significantly impact operational efficiency and product presentation. Among various options, Corrugated Plastic Rolls have gained popularity due to their versatility and durability. According to a report by Smithers Pira, the global market for plastic packaging is expected to reach $470 billion by 2025, reflecting a growing demand for materials like corrugated plastics that offer lightweight yet sturdy solutions for shipping, storage, and display purposes. As businesses strive for sustainable practices, the recyclable nature of Corrugated Plastic Rolls also aligns with eco-friendly initiatives, making them a smart choice for companies looking to reduce their environmental footprint. This ultimate guide aims to navigate the selection process, providing essential tips to help businesses tailor their choices to better meet specific needs and maximize value.

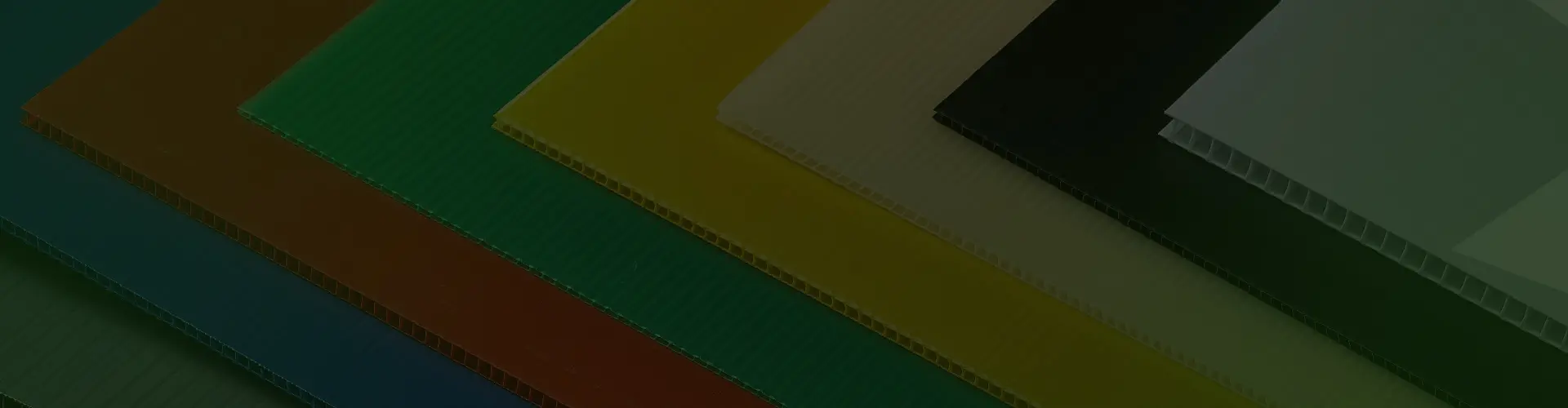

Understanding the Different Types of Corrugated Plastic Rolls Available in the Market

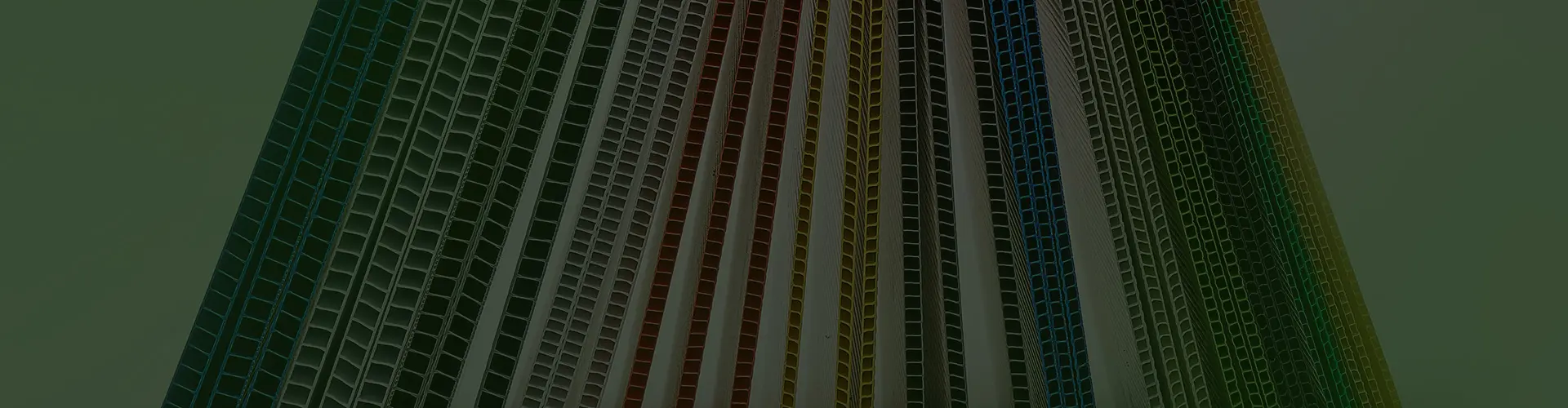

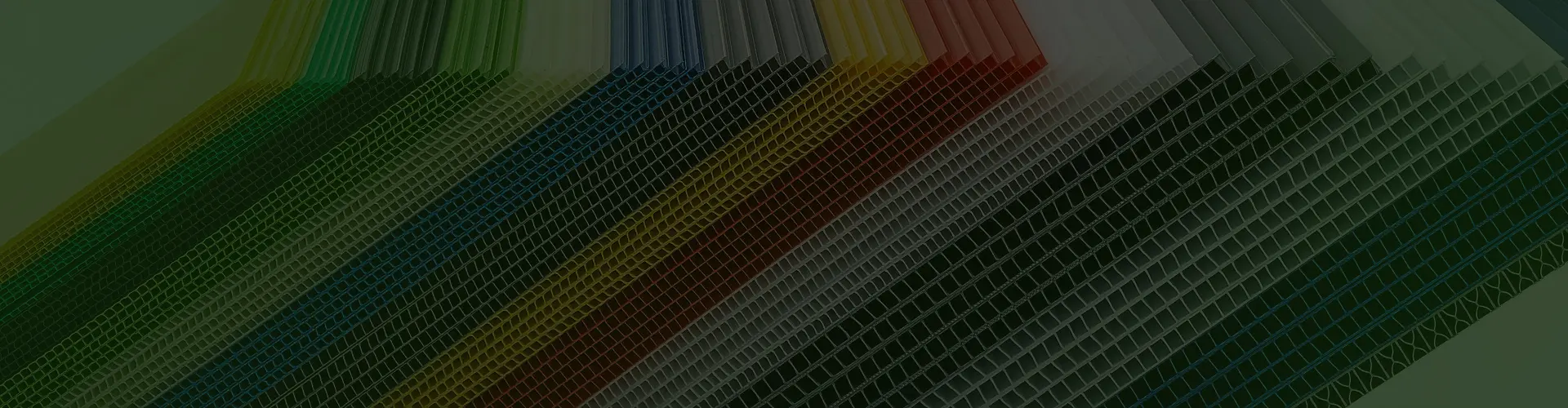

When selecting the right corrugated plastic rolls for your business, understanding the types available in the market is crucial. Corrugated plastic rolls, made from durable polypropylenes, are renowned for their lightweight yet robust properties, making them a popular choice for various applications, from packaging to signage. These rolls come in multiple forms, including single-walled and double-walled configurations, each offering different levels of strength and insulation depending on your project's requirements.

There are several variations of corrugated plastic rolls beyond just size and thickness. For instance, you can find options that are UV-resistant, making them suitable for outdoor use, as well as those that are designed for specific industries like food packaging or retail displays. Understanding these nuances allows businesses to choose products that not only meet their functional needs but also align with environmental requirements, as more companies seek sustainable packaging solutions.

Thus, evaluating the different types of corrugated plastic available can significantly impact efficiency and cost-effectiveness in your operations.

Key Factors to Consider When Selecting Corrugated Plastic Rolls for Specific Applications

When selecting corrugated plastic rolls for specific applications, it's essential to consider factors such as material durability, thickness, and environmental conditions. According to a recent report by Smithers Pira, the global demand for corrugated plastics is expected to reach over 5.5 million metric tons by 2025, driven by their lightweight properties and resilience. For businesses in packaging and signage, choosing the right thickness is critical, as thinner rolls may bend or tear under stress, while overly thick rolls can be cumbersome and expensive. Common thickness ranges from 3mm to 12mm, with applications varying based on specific requirements.

Another important aspect is the environmental resistance of the corrugated plastic being selected. Many applications, like outdoor signage or agricultural uses, require materials that withstand UV exposure and varying weather conditions. The 2021 Plastics Industry Association study highlighted that UV stabilization can extend the lifespan of corrugated plastics by up to 50%, significantly benefiting businesses that rely on longevity and durability in their products. Understanding the operational environment and any exposure to chemicals or extreme temperatures is crucial for ensuring that the corrugated plastic will perform as needed throughout its intended lifespan.

Ultimate Guide to Choosing the Right Corrugated Plastic Rolls for Your Business Needs

| Application | Roll Size | Thickness | Weight (lbs per roll) | Color Options | UV Resistance | Waterproof |

|---|---|---|---|---|---|---|

| Signage | 48" x 100' | 4mm | 20 | White, Yellow, Blue | Yes | Yes |

| Displays | 36" x 75' | 3mm | 15 | Clear, Black | Yes | Yes |

| Packaging | 24" x 50' | 2mm | 10 | White | No | Yes |

| Construction | 60" x 100' | 5mm | 30 | Gray, Blue | Yes | Yes |

Analyzing Cost-Effectiveness: Long-Term Benefits of Investing in Quality Corrugated Plastic Rolls

When considering the long-term benefits of investing in quality corrugated plastic rolls for your business, it's essential to analyze their cost-effectiveness. Unlike conventional plastics, which contribute to significant environmental challenges, quality corrugated plastic rolls offer a sustainable alternative. They are lightweight yet durable, making them cost-efficient for storage and transport. Additionally, their recyclability aligns with the principles of a circular economy, reducing waste and promoting environmental stewardship.

Recent studies highlight the pressing need for industries to adopt more sustainable practices amidst growing concerns over plastic pollution. The development and use of advanced materials, such as biodegradable plastics and innovative recycling technologies, suggest a shift towards a more resilient supply chain. Investing in high-quality corrugated plastic rolls not only enhances operational efficiency but also supports efforts to mitigate the microplastic crisis. By choosing quality products, businesses can ensure they are contributing positively to both their bottom line and the environment, ultimately paving the way for a more sustainable future.

Industry Trends: How Sustainability Influences the Choice of Corrugated Plastic Materials

The growing emphasis on sustainability is significantly shaping the selection of corrugated plastic materials in various industries. As businesses become more environmentally conscious, they are increasingly opting for materials that not only meet their functional needs but also align with their sustainability goals. Corrugated plastic, renowned for its durability and lightweight characteristics, is now being manufactured using recycled materials or processes that minimize waste. This shift not only reduces the carbon footprint associated with production but also supports a circular economy, where materials are reused and recycled.

Additionally, companies are recognizing the importance of certifications and standards that gauge the environmental impact of their materials. Choosing corrugated plastics from suppliers that prioritize sustainable practices can enhance a business’s brand image and appeal to eco-minded consumers. As industries continue to evolve, those that strategically select sustainable corrugated plastic options will find themselves not only meeting regulatory demands but also fostering customer loyalty in a marketplace increasingly driven by environmentally friendly practices.

Maximizing Durability: Identifying the Best Thickness and Density for Your Business Needs

When selecting corrugated plastic rolls for your business, understanding the importance of thickness and density is crucial to maximizing durability. Thicker materials often provide enhanced strength and resistance to wear and tear, making them ideal for high-traffic environments. Conversely, a lighter, less dense option might be suitable for projects requiring flexibility and easier handling. Therefore, it's essential to assess the specific demands of your application before making a choice.

Tip: Consider the environmental factors your corrugated plastic will face. For outdoor usage, a thicker and denser product can withstand UV rays and varying weather conditions, offering longevity and protecting your investment. For temporary displays or indoor use, a lighter gauge may suffice, reducing costs while still meeting your needs.

Another important factor to keep in mind is the intended use. If the rolls will support heavy materials or be subjected to repetitive movement, selecting a higher-density option can prevent buckling and deformation over time. This attention to material characteristics ensures that your business utilizes the right corrugated plastic rolls for optimal performance.

Ultimate Guide to Choosing the Right Corrugated Plastic Rolls

This chart illustrates the relationship between thickness, density, and the durability rating of different types of corrugated plastic rolls suitable for various business needs.

Related Posts

-

Unlocking the Advantages of Using the Best Corrugated Plastic Rolls for Your Business Needs

-

Uncompromising Quality Yellow Corrugated Plastic Crafted in China for Global Success

-

Unmatched Quality in Best Plastic Corrugated Pads: China’s Leading Export Solution

-

Ultimate Guide to Sourcing White Corrugated Plastic: Everything Global Buyers Need to Know

-

Ultimate Guide to Sourcing High Quality Plastic Corrugated Sheets for Diverse Applications

-

Top 10 Manufacturers of White Corrugated Plastic from China at the 137th Canton Fair