- export5@runpingpp.com

- 24 Hours Online

Industry News

Future Market Insights and Trends for Best Corrugated PP by 2025 in the Packaging Industry

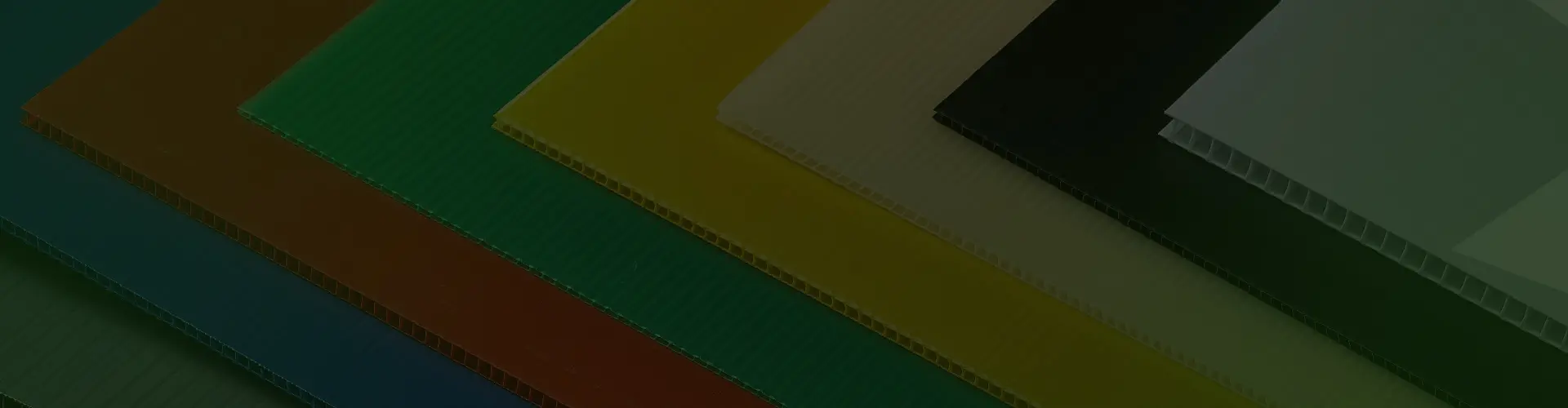

In the rapidly evolving packaging industry, Corrugated PP (Polypropylene) has emerged as a vital material that combines strength and versatility, making it suitable for a wide range of applications. According to a report by Future Market Insights, the global demand for corrugated packaging is expected to reach substantial growth, projected to surpass $250 billion by 2025. This growth is fueled by the increasing need for sustainable and lightweight packaging solutions, particularly in sectors such as food, electronics, and consumer goods. As industries prioritize eco-friendly alternatives, Corrugated PP stands out for its recyclability and durability, providing both economic and environmental benefits. This blog will explore the distinct characteristics and applications of various types of Corrugated PP products, offering insights into market trends and user preferences that are shaping the future of the packaging landscape.

Key Drivers Influencing the Future of Corrugated PP in Packaging Industry

The packaging industry is on the brink of transformation, particularly with regard to corrugated polypropylene (PP) solutions. Key drivers influencing its future include the growing demand for sustainable packaging, advancements in manufacturing technology, and the increasing need for lightweight materials. As consumers become more environmentally conscious, brands are under pressure to adopt eco-friendly practices. This has led to a rise in the preference for recyclable and reusable materials, positioning corrugated PP as a viable solution due to its durability and recyclability.

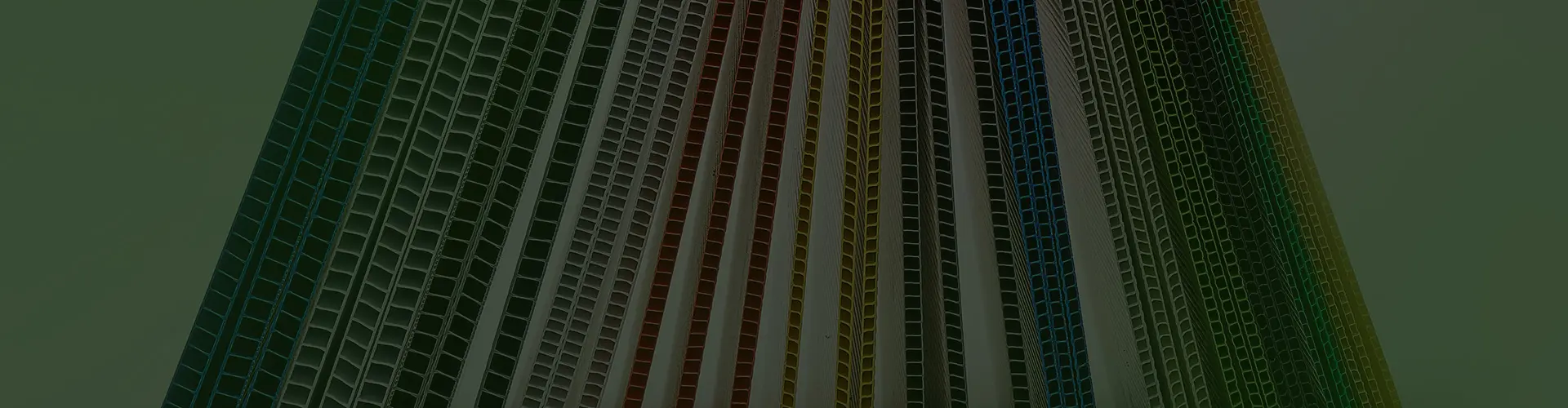

Innovations in production techniques are also playing a crucial role in the evolution of corrugated PP. Advanced manufacturing processes are enabling the creation of more versatile and tailored packaging options that meet specific industry requirements. Moreover, the emphasis on reducing shipping costs and improving operational efficiency is pushing companies to explore lightweight packaging solutions. As a result, the integration of corrugated PP allows businesses to achieve cost-effective logistics while maintaining high standards of protection for their products.

As we look toward 2025, these factors will undoubtedly shape the landscape of the packaging industry, steering it towards a more sustainable and efficient future.

Emerging Trends in Sustainable Practices for Corrugated PP Packaging

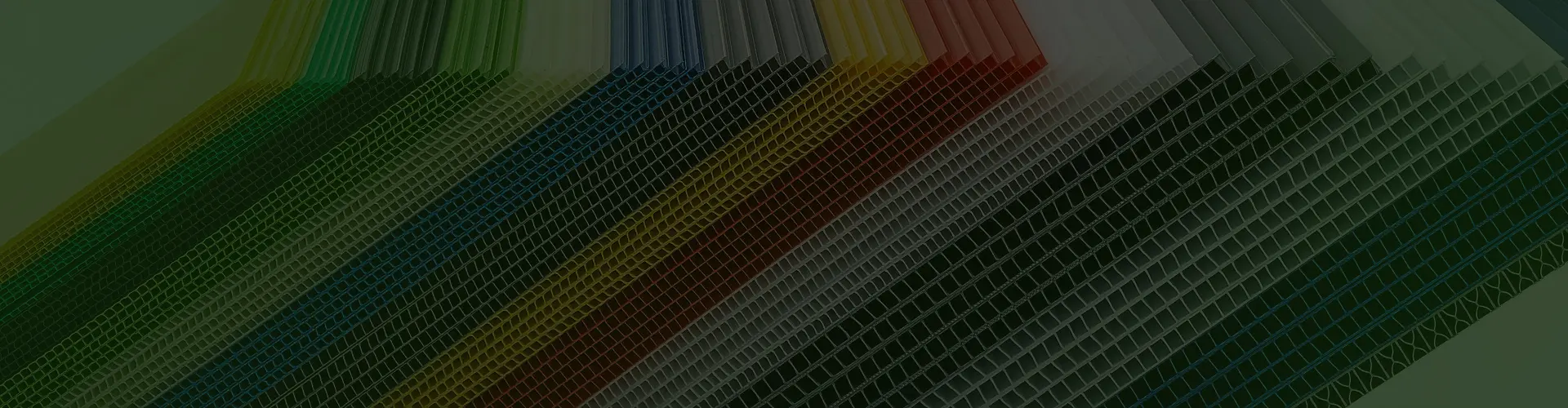

Sustainable practices in the packaging industry are becoming increasingly crucial, especially for corrugated polypropylene (PP) materials. According to a report by Future Market Insights, the global demand for sustainable packaging solutions is expected to witness a CAGR of 5.7% from 2020 to 2025, with corrugated PP packaging being a significant segment due to its recyclability and durability. Companies are now prioritizing eco-friendly materials that not only reduce waste but also enhance brand image among environmentally conscious consumers.

To adapt to these emerging trends, businesses seeking to optimize their packaging should consider implementing the following tips: first, invest in biodegradable additives that can be mixed with corrugated PP to enhance its environmental profile. Additionally, think about adopting a circular economy model, where used packaging materials are recycled and reused in new products. By doing so, firms can minimize their carbon footprint while meeting the evolving demands of customers who are increasingly supportive of sustainable practices.

Moreover, integrating smart technologies, such as QR codes on corrugated PP packaging, can provide consumers with information about the sourcing, recycling processes, and environmental impact of the packaging. This transparency not only builds trust but also aids in educating consumers about making eco-friendly choices, bolstering the shift towards a more sustainable packaging landscape.

Innovative Technologies Shaping Corrugated PP Production by 2025

Innovative technologies are rapidly transforming the production of corrugated polypropylene (PP) in the packaging industry. By 2025, we can expect advancements such as automation in manufacturing processes, the integration of artificial intelligence for quality control, and the use of sustainable materials. These innovations not only enhance efficiency but also reduce waste, leading to a greener packaging solution. Companies that embrace these technologies will likely gain a competitive edge in an evolving market.

To stay ahead, businesses can consider investing in research and development focused on eco-friendly materials and production methods. Collaborating with tech firms can also provide insights into new machinery and processes that improve production speed and reduce costs. Furthermore, attending industry conferences and trade shows can offer valuable networking opportunities and exposure to cutting-edge technology that may reshape packaging.

Tip: Implementing a feedback loop with customers regarding packaging performance can lead to better-designed products that meet market demands. Another tip is to regularly assess and upgrade equipment to leverage the latest technological advancements in production. Keeping an eye on industry trends will ensure your company remains at the forefront of corrugated PP packaging innovations.

Future Market Insights and Trends for Best Corrugated PP by 2025

This chart illustrates the projected production volume of corrugated polypropylene (PP) from 2019 to 2025. It shows a steady growth trajectory, highlighting the increasing adoption of innovative technologies within the packaging industry that are expected to drive production efficiency and capacity.

Competitive Landscape: Key Players and Market Dynamics in Corrugated PP

The corrugated polypropylene (PP) market is rapidly evolving, driven by increasing demand for sustainable packaging solutions across various industries. Key players in the competitive landscape are continuously innovating to enhance their product offerings, focusing on durability, lightweight characteristics, and eco-friendliness. Major companies such as Sealed Air Corporation and AEP Industries Inc. are investing in advanced manufacturing technologies to improve efficiency and reduce environmental impact, making their corrugated PP products more appealing to a broader range of customers.

The corrugated polypropylene (PP) market is rapidly evolving, driven by increasing demand for sustainable packaging solutions across various industries. Key players in the competitive landscape are continuously innovating to enhance their product offerings, focusing on durability, lightweight characteristics, and eco-friendliness. Major companies such as Sealed Air Corporation and AEP Industries Inc. are investing in advanced manufacturing technologies to improve efficiency and reduce environmental impact, making their corrugated PP products more appealing to a broader range of customers.

When navigating this dynamic market, companies should consider these tips: First, prioritize sustainability in product design, as consumers are increasingly inclined towards eco-conscious brands. Second, leverage technological advancements to optimize production processes and lower costs without compromising quality. Lastly, stay updated on market trends and consumer preferences to align product development with emerging demands. By adopting these strategies, businesses can effectively position themselves in the competitive corrugated PP landscape.

Collaboration and strategic partnerships are also becoming crucial in this industry. Companies are forming alliances to enhance their supply chain capabilities and broaden their market reach. These collaborations not only foster innovation but also enable players to share resources and expertise, paving the way for a more resilient market presence.

Consumer Preferences: Shifting Demands for Corrugated PP Packaging Solutions

The shifting consumer preferences in the packaging industry are increasingly favoring sustainable solutions, particularly within the realm of corrugated polypropylene (PP) packaging. As awareness around plastic pollution grows, consumers are now prioritizing eco-friendly options, which has directed the focus toward corrugated PP materials known for their recyclability and minimal environmental impact. This transformation is instrumental as the India Corrugated Packaging Market is projected to surge from USD 25 billion in 2024 to USD 47.5 billion by 2035, reflecting a dramatic rise in demand for sustainable packaging solutions.

Moreover, the global corrugated board packaging market is expected to generate significant revenue, anticipated to reach approximately USD 420 billion by 2032. This growth underscores the dominance of corrugated boxes, which are not only preferred for their sturdiness but also for their adaptability in various applications. As manufacturers align their strategies to meet these emerging consumer preferences, there is a notable shift towards integrating recycled and upcycled materials into packaging designs. These innovative changes not only address the sustainability concerns but also create new market opportunities for brands willing to invest in environmentally responsible practices.