- export5@runpingpp.com

- 24 Hours Online

Industry News

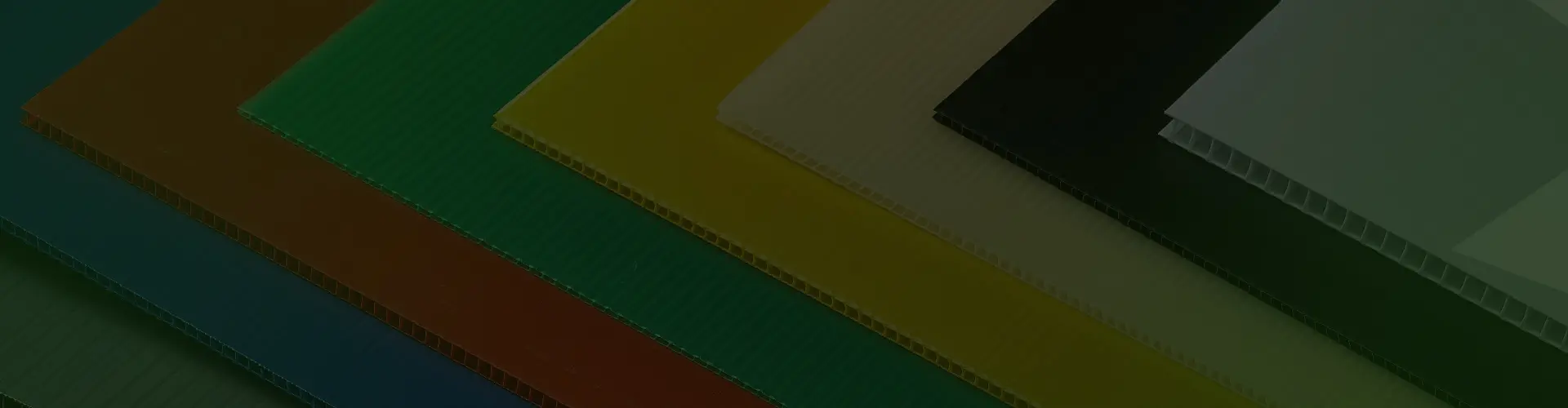

How to Choose the Right Corrugated Plastic Board for Your Business Needs

In today's competitive market, choosing the right materials for your business operations is crucial, and one such material gaining attention is the Corrugated Plastic Board. According to a recent market analysis by Smithers Pira, the global demand for corrugated plastics is expected to grow at a CAGR of 4.1% over the next five years, reaching an estimated market value of $7 billion. This growth is attributed to the increasing need for lightweight, durable, and recyclable materials across various industries, including packaging, advertising, and construction.

With its impressive versatility and weather-resistant properties, Corrugated Plastic Board proves to be an excellent choice for businesses looking to enhance their operational efficiency. However, selecting the right type for your specific needs can be a daunting task. In this blog, we will delve into essential tips and key factors to consider when choosing Corrugated Plastic Boards to ensure they align perfectly with your business requirements.

Key Factors to Consider When Selecting Corrugated Plastic Boards

When selecting corrugated plastic boards for your business needs, there are several key factors to consider. The global corrugated board packaging market is projected to reach $191.50 billion by 2032, indicating a significant increase in demand. Understanding the specific requirements for your application—such as weight, durability, and environmental resistance—can help in making the right choice. For instance, if your product will be exposed to harsh weather conditions, opting for UV-resistant boards may be beneficial.

**Tip:** Always evaluate the thickness of the board; thicker boards provide better structural integrity and can better handle heavy loads.

Another important factor is the board's recyclability. With the global emphasis on sustainability, selecting eco-friendly materials can enhance your brand's reputation. The right corrugated plastic boards not only meet your business needs but also align with growing environmental concerns, ensuring your packaging solutions are both effective and responsible.

**Tip:** Consider conducting a cost-benefit analysis to weigh the long-term savings of using recyclable materials against initial expenses. This can reveal hidden advantages that will support your business’s sustainability goals while optimizing packaging performance.

How to Choose the Right Corrugated Plastic Board for Your Business Needs

Comparing Different Types of Corrugated Plastic for Various Applications

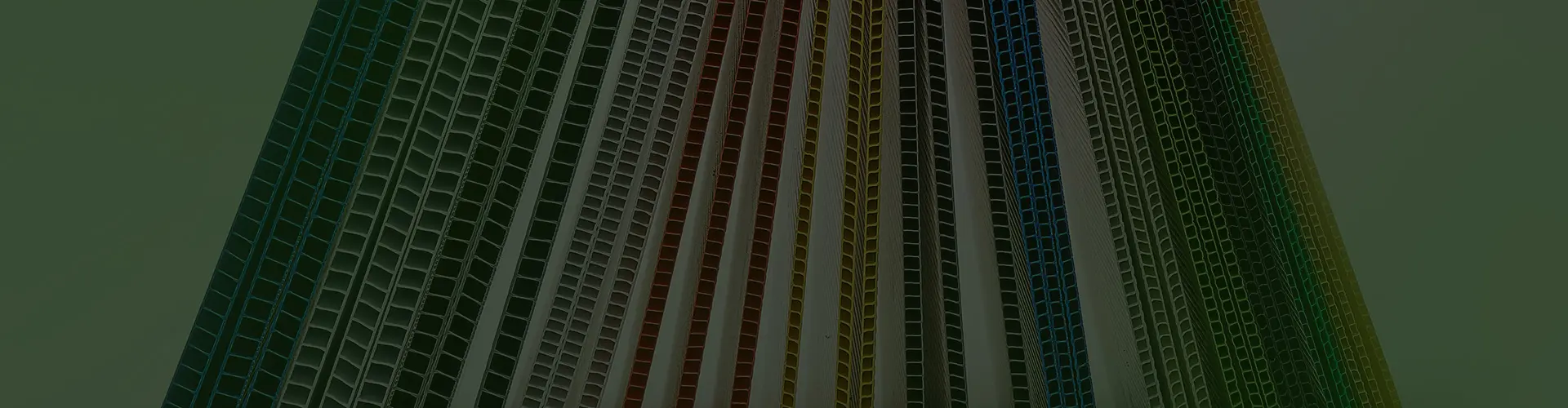

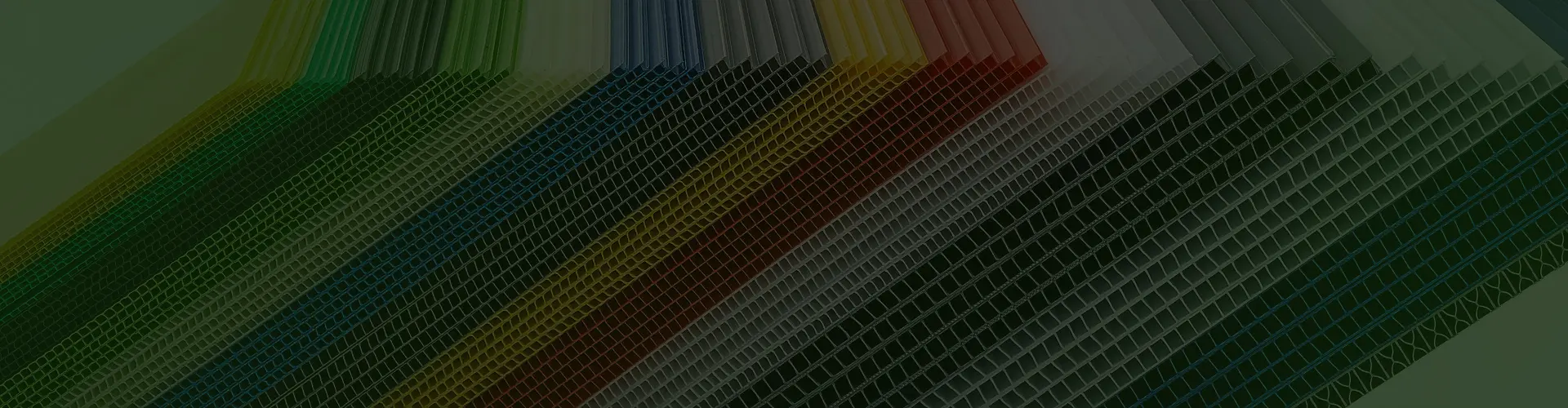

When choosing the right corrugated plastic board for your business needs, it's essential to consider the various types available and their specific applications. Corrugated plastic boards come in multiple variations, including twin-wall, triple-wall, and single-wall configurations. According to a recent report from the Plastics Industry Association, the demand for corrugated plastic sheets is expected to grow by 4.5% annually, driven by their versatile nature in industries such as retail, construction, and agriculture.

For example, twin-wall boards, known for their lightweight and durable nature, are ideal for temporary signage and packaging solutions. Their UV stability makes them suitable for both indoor and outdoor use. On the other hand, triple-wall boards offer superior strength and rigidity, making them excellent for heavy-duty applications and shipping solutions. A study from the American Plastics Council indicates that industries utilizing triple-wall corrugated boards see a 30% reduction in material costs due to their increased durability and reusability compared to traditional packaging materials. Selecting the right type based on specific operational needs can significantly enhance efficiency and sustainability in your business operations.

Durability and Strength: Assessing the Right Board for Your Needs

When choosing the right corrugated plastic board for your business needs, durability and strength should be your primary considerations. Just as with other construction materials, the longevity of your chosen board impacts not only your costs but also your operational efficiency.

Assessing the mechanical properties of corrugated plastic boards, such as their resistance to impact and bending, will ensure that you select a product that withstands the demands of your application.

Tips for selecting the right board include examining its thickness and the type of polymers used in its construction. Thicker boards generally offer better resistance to wear and tear, while high-quality polymers enhance both durability and strength. Additionally, consider the environmental impact of your material choices. As the construction industry trends toward sustainability, opting for boards made from recycled materials can contribute to reduced waste and a smaller carbon footprint.

Moreover, keep in mind the potential for customization. Different applications may necessitate specific qualities, such as moisture resistance or UV stability. When selecting a corrugated plastic board, balancing durability with these functional requirements will help you meet your particular business objectives effectively.

Cost-Effectiveness: Finding Budget-Friendly Options Without Compromising Quality

When selecting corrugated plastic boards for your business, cost-effectiveness is key. A well-thought-out budget doesn’t mean you have to compromise on quality. Look for suppliers that offer discounts on bulk orders or are willing to negotiate prices. This can be a game-changer in helping you acquire high-quality materials without overspending.

Tips: Always request samples before making a large purchase. This allows you to assess the board’s durability and suitability for your needs. Additionally, consider checking customer reviews and testimonials to get an idea of the product quality offered by various manufacturers.

Another savvy approach is to compare different brands carefully. While it might be tempting to go with the cheapest option available, ensure that you're not sacrificing essential features such as thickness and weather resistance. Investing a bit more in a reliable board can save you money in repairs or replacements down the line.

Tips: Set a clear specification of what you need from the boards and communicate this to the suppliers. This will help you find options that fit both your budget and quality expectations more readily.

Environmental Impact: Evaluating Eco-Friendly Choices in Corrugated Plastics

When selecting corrugated plastic boards for your business needs, it's crucial to consider their environmental impact. Traditionally, plastic materials have faced criticism due to their contribution to pollution and waste. However, advancements in manufacturing have led to the development of more eco-friendly options. Many companies now offer corrugated plastic boards made from recycled materials or those designed to be recyclable themselves. By choosing these sustainable products, businesses can significantly reduce their carbon footprint while still enjoying the durability and versatility that corrugated plastics provide.

Moreover, evaluating the eco-friendliness of various corrugated plastics involves looking at their life cycle. Consider factors such as production methods, transport emissions, and end-of-life disposal. Some boards are treated to be UV-resistant and weatherproof, which enhances their longevity and ultimately reduces the need for frequent replacements. This aspect not only benefits the environment but also promotes cost-efficiency in the long term. By taking the time to assess the sustainability of your material choices, you can align your business operations with eco-conscious values, appealing to an increasingly environmentally-aware consumer base.

Related Posts

-

Advantages of Using Best Corrugated Plastic Rolls for Your Business Needs

-

Exceptional Manufacturing of Best Corrugated Plastic from China Serving the Global Market

-

Ultimate Guide to Sourcing White Corrugated Plastic: Everything Global Buyers Need to Know

-

Issues with Sourcing Corrugated Box Plastic Solutions for International Buyers

-

Ultimate Guide to Creating Effective Corrugated Signs for Your Business

-

Unlocking the Advantages of Using the Best Corrugated Plastic Rolls for Your Business Needs