- export5@runpingpp.com

- 24 Hours Online

Industry News

Why Choose Corrugated Plastic Rolls for Your Next Project?

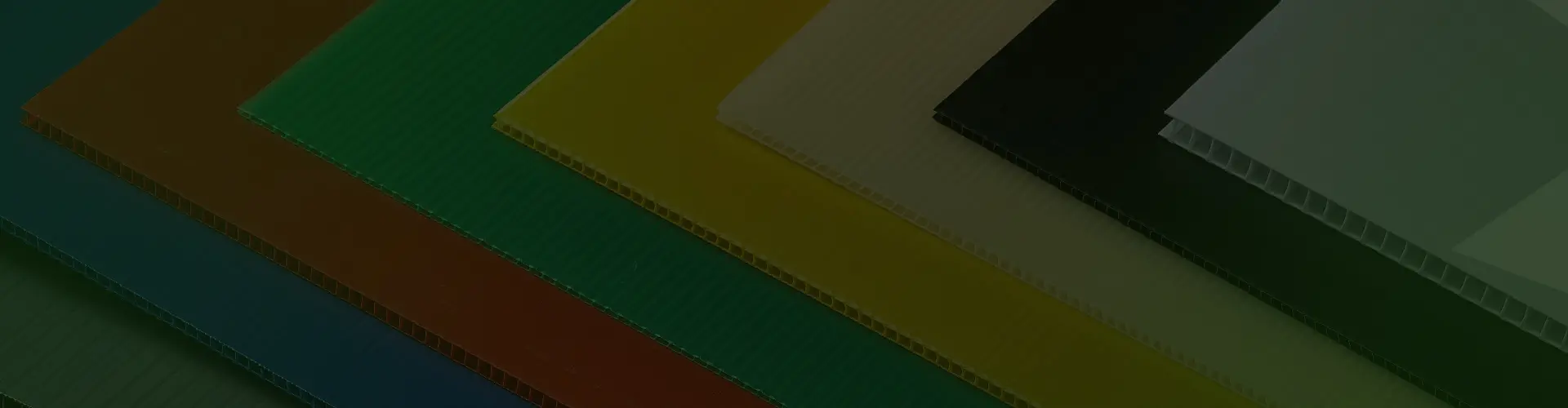

When embarking on a new project, selecting the right materials can significantly impact both the process and results. One material that has gained popularity among various industries is "Corrugated Plastic Rolls." Known for their versatility and durability, these rolls offer a multitude of advantages that make them an ideal choice for both temporary and permanent applications. From packaging to signage and construction projects, corrugated plastic provides a lightweight yet robust solution that can withstand the test of time.

The appeal of corrugated plastic rolls lies not only in their physical properties but also in their eco-friendliness. Made from recycled materials, they are a sustainable alternative to traditional plastic products, making them a responsible choice for environmentally-conscious consumers. Furthermore, the ease of handling and customization of these rolls ensures that they can be tailored to meet the specific needs of any project, whether for indoor use or outdoor exposure.

In summary, "Corrugated Plastic Rolls" stand out for their practicality, sustainability, and adaptability. As industries continue to look for efficient and effective materials, these rolls provide a compelling option that meets diverse requirements. Choosing corrugated plastic for your next project may lead to significant benefits, ultimately enhancing both functionality and environmental stewardship.

Benefits of Using Corrugated Plastic Rolls in Various Projects

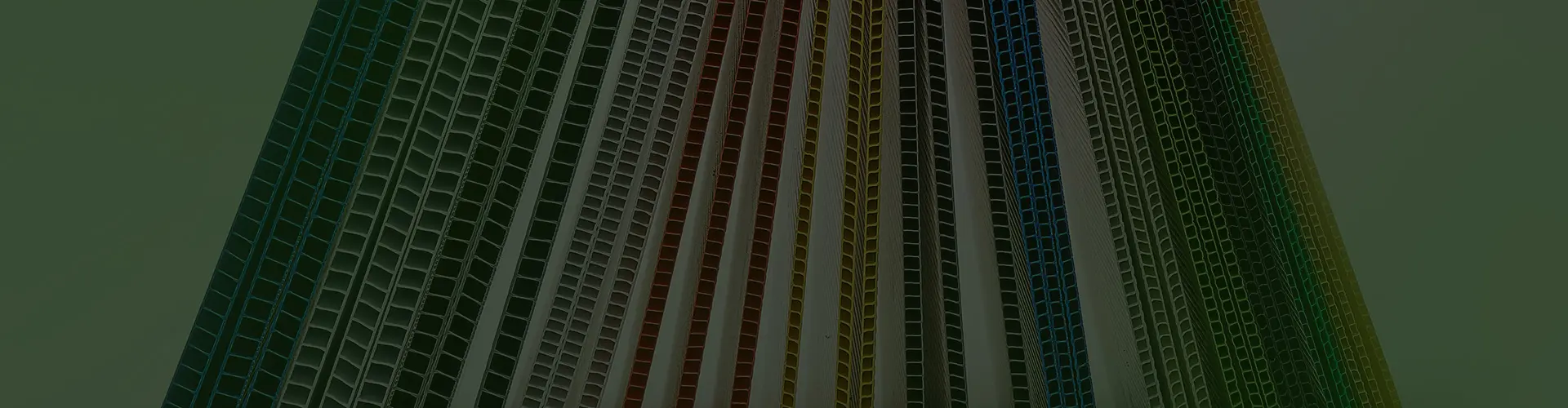

Corrugated plastic rolls have become a popular choice in various projects due to their versatile applications and significant advantages. One of the primary benefits of using these rolls is their lightweight yet durable nature. This makes them easy to handle and transport, reducing labor costs and time on-site. Whether used for signage, temporary barriers, or packaging, corrugated plastic offers strength without the added weight, making it an ideal solution for both construction projects and event setups.

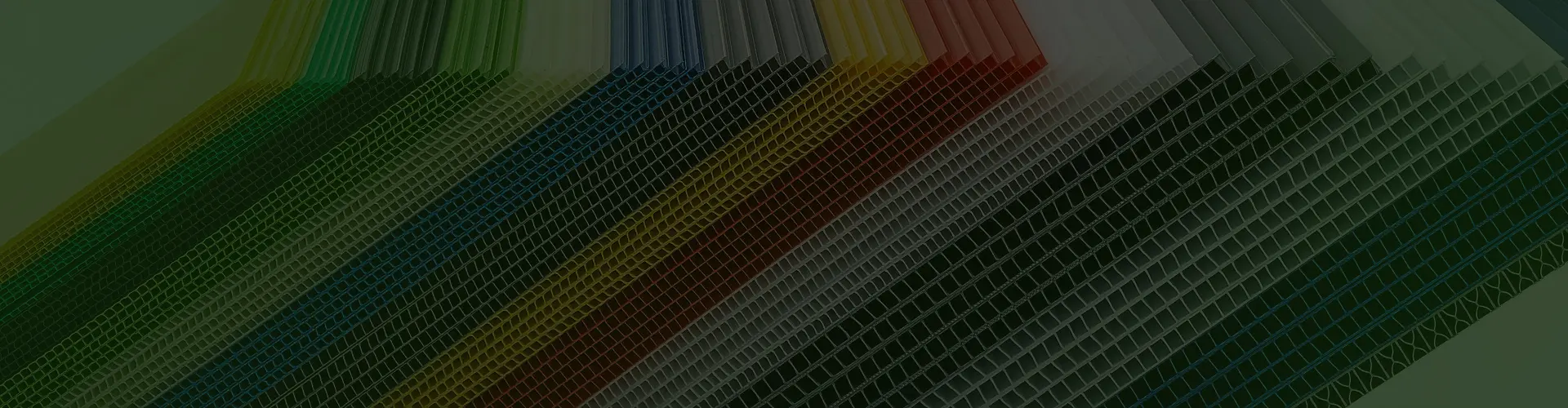

In addition to their durability and ease of use, corrugated plastic rolls are also resistant to water, chemicals, and UV rays. This resistance ensures that the materials maintain their integrity and appearance even when exposed to harsh weather conditions or substances that could cause damage to other materials. Furthermore, they are recyclable, making them an environmentally friendly option for temporary and permanent installations. The ability to customize these rolls in size and color adds another layer of adaptability, ensuring that they meet the specific needs of diverse projects.

Durability and Weather Resistance of Corrugated Plastic Rolls

Corrugated plastic rolls are becoming increasingly popular across various industries due to their remarkable durability and weather resistance. Unlike traditional materials, corrugated plastic is engineered to withstand harsh environmental conditions, making it an ideal choice for outdoor applications. According to a report by Research and Markets, the demand for durable materials in construction has grown by over 25% in the last five years, largely driven by the need for long-lasting solutions that can endure extreme weather conditions. Corrugated plastic rolls provide exceptional resistance to moisture, UV rays, and temperature fluctuations, significantly reducing the risk of degradation over time.

Moreover, the resilience of corrugated plastic not only benefits structural integrity but also enhances the overall cost-effectiveness of projects. A study published by the American Society of Civil Engineers indicates that using durable materials can lead to a 30% reduction in maintenance costs over a project’s lifespan. This durability translates to fewer replacements and repairs, allowing professionals to allocate resources more efficiently. The lightweight nature of corrugated plastic rolls also ensures ease of handling and installation, further streamlining project workflows. As industries continue to prioritize sustainability and longevity, corrugated plastic emerges as a reliable choice that aligns with modern engineering and environmental standards.

Why Choose Corrugated Plastic Rolls for Your Next Project? - Durability and Weather Resistance of Corrugated Plastic Rolls

| Feature | Description | Benefits |

|---|---|---|

| Durability | Resistant to impacts, bending, and crushing | Long-lasting materials suitable for various applications |

| Weather Resistance | Withstands rain, snow, and UV radiation | Ideal for outdoor use without degradation |

| Lightweight | Easy to handle and transport | Reduces shipping costs and improves productivity |

| Versatility | Suitable for a wide range of applications | Flexible for projects in different industries |

| Cost-Effectiveness | Affordable compared to other materials | Provides value without compromising quality |

Versatility of Applications for Corrugated Plastic Rolls

Corrugated plastic rolls are celebrated for their remarkable versatility, making them an ideal choice for a wide range of applications across various industries. One of their most significant features is their lightweight yet durable construction, which allows them to be utilized in both temporary and permanent setups. For example, they are commonly used in signage, protective barriers, and packaging solutions. Their waterproof and weather-resistant nature ensures that they can withstand diverse environmental conditions, making them a reliable option for outdoor projects.

In addition to signage and packaging, corrugated plastic rolls find applications in agriculture and construction. In agriculture, they serve as effective planting trays or crop protection covers, helping to improve yields while simplifying farming practices. Similarly, in construction, they can be used as protective coverings for surfaces, preventing dirt and damage during renovations or building processes. The flexibility and ease of manipulation of these rolls enable quick adjustments to various project needs, setting the stage for innovative solutions in both commercial and residential settings.

Cost-Effectiveness of Corrugated Plastic Rolls in Project Management

Corrugated plastic rolls have gained popularity in project management due to their remarkable cost-effectiveness and versatility. According to a report by MarketsandMarkets, the demand for corrugated plastic products is expected to grow at a CAGR of 5.3% from 2021 to 2026, indicating a robust trend toward materials that offer both performance and savings. Utilizing corrugated plastic rolls often results in lower overall project costs, as they are lightweight, reducing shipping expenses and labor costs associated with handling and installation.

Furthermore, the durability of corrugated plastic plays a significant role in its cost-effectiveness. Research from the Plastics Industry Association shows that these materials can last up to five times longer than traditional options like cardboard, which often need frequent replacements. This long lifespan translates to lower long-term expenses and reduced waste, reinforcing the financial benefits of choosing corrugated plastics. Additionally, their ability to withstand various environmental conditions makes them suitable for a wide range of applications, thereby maximizing value across different projects.

By leveraging the advantages of corrugated plastic rolls, project managers can streamline their operations and achieve more sustainable outcomes, reflecting a growing shift toward smarter, more economical material choices in the industry.

Cost-Effectiveness of Corrugated Plastic Rolls in Project Management

Environmental Impact and Recyclability of Corrugated Plastic Rolls

Corrugated plastic rolls, often made from high-density polyethylene (HDPE) or polypropylene, offer significant advantages in terms of environmental impact and recyclability. According to a report from the Plastics Industry Association, over 75% of plastics can be recycled. Corrugated plastic is no exception, as its composition allows for a closed-loop recycling process that reduces the need for virgin materials. When properly recycled, these materials can be repurposed into new products, minimizing waste and the consumption of natural resources.

Additionally, corrugated plastic rolls' lightweight yet durable nature contributes to reduced transportation emissions. A study by the Environmental Protection Agency highlights that efficient material handling can estimate a carbon footprint reduction of up to 30% for products during distribution. This benefit is not just limited to transportation; the longevity and resistance of corrugated plastic to weathering and chemicals also mean that these materials remain in use longer, which prolongs their lifecycle and reduces the frequency of replacements needed. By choosing corrugated plastic rolls, companies not only make a sustainable choice for their projects, but they also contribute to a more circular economy.

Related Posts

-

Uncompromising Quality Yellow Corrugated Plastic Crafted in China for Global Success

-

7 Best Benefits of Using Corrugated Plastic Rolls in Global Packaging Solutions

-

What is a PP Corrugated Plastic Box? Benefits and Uses Explained

-

Exploring the Benefits of Using White Corrugated Plastic for Your Business Needs

-

The Ultimate Guide to Understanding the Benefits of Plastic Corrugated Pads in Packaging Solutions

-

How to Choose the Right Corrugated Plastic for Your Business Needs: Insights and Industry Statistics